How to choose an air compressor, what parameters should I pay attention to?

An air compressor is a tool that is actively used in various fields: medicine, service stations, construction sites, carpentry shops and many others. Without a compressor, pneumatic tool operation is not possible. However, for everything to work as it should, you should be aware of the features of different types of compressors. How to choose a compressor and what to look at, we will consider in this article.

Basic principles of compressor operation

The principle of operation of this unit is similar to the operation of a conventional pump. The compressor not only pumps air, but also compresses it in the receiver, which increases the pressure and speed of air transfer. Therefore, one of the most important parameters of these units is the outlet pressure, for its control they are equipped with special pressure gauges.

Already compressed air is then fed through special adapters to a pneumatic tool or other technical device connected to the compressor. Different compressor models can be based on an electric or gasoline engine. In addition, different models may vary in size, power, phase and other parameters.

To choose the right compressor, you need to decide on some important characteristics. Which compressor to choose for production or for the house, what engine power is required? To answer these and other questions of concern to customers, we will consider the main criteria that affect the choice of the unit.

Types of compressors

There are two main types: piston and screw.

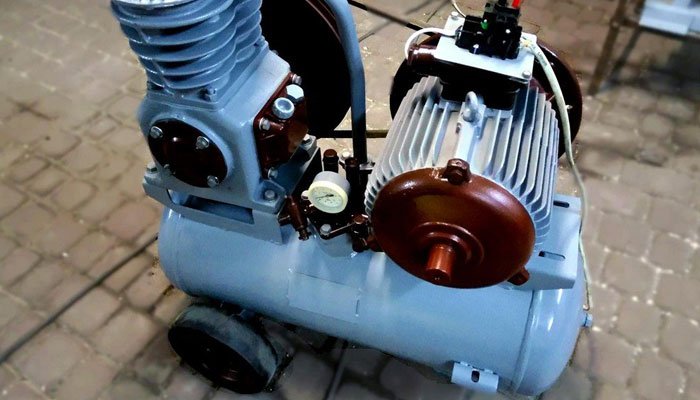

Reciprocating

In models of this type, a special piston block compresses the air. Pistons are located in the cylinder and inside it move vertically. This is a practical type of compressor. They are comfortable and popular due to their rather low price. However, it is worth considering such a feature as a limited working time. At the same time, they have high technical parameters, therefore they are actively used not only in everyday life, but also in small industries. Since they are equipped with internal combustion engines, it is necessary to provide good ventilation in the room where this device will work.

Screw

In such compressors, air is injected using two rotating screws (rotors). Moreover, the screws do not move, like pistons, up and down. They spin very fast, creating a powerful centrifugal force. It is worth noting that screw units have better characteristics, higher efficiency and increased resource, compared to piston ones. In addition, they can work for a long time without stopping. They are usually chosen for use in various enterprises, in everyday life they are rarely used because of the high cost.

Power Type

Compressors can be equipped with an electric or gasoline engine. For household use, for installation in service stations, in paint shops or small industrial facilities, models with electric motors are better suited. Their advantage is ease of maintenance and the ability to work from a network with a voltage of 380 and 220V.

Models with gasoline engines are more expensive, while they are more powerful, more overall and heavy. Buying them for the needs of small enterprises, and even more so for household operation, is unprofitable. They require frequent and more complex maintenance. These options are more suitable for professional use when you need power and performance.

Transfer Type

Another important parameter on which the power, reliability and duration of the air compressor depends is the type of drive. It can be: direct and belt. Here the names speak for themselves.

Direct Drive

Devices of this type have a simple pass motor torque, it is used only in piston models. There is a connecting rod mechanism installed directly, without the use of gears or flywheels. These compressors are perfect for a variety of domestic applications.

Models with direct drive hold the load well, do not allow the system to overheat, since in them the temperature is reliably regulated by the blower system. They work quietly, without unnecessary noise and quite smoothly, they are distinguished by good performance and high efficiency.

Belt drive

Compressors of this type have two impellers (master and slave) and a belt drive between them. The main power plant is closed with a special protective cover that prevents small objects from getting inside that can cause serious harm and ruin the mechanism. It is worth paying attention to the fact that the belt drive can be used in reciprocating and screw compressors.

End of form

Main technical parameters

Air consumption

Perhaps this is one of the most important indicators, which depends on the power of the motor installed on the device and the type of construction. Be careful. As a rule, manufacturers indicate the figure of the inlet flow rate and often do not take into account the error in the outlet. For example, in household models, this indicator can be indicated as 200 l/min. The average value of the error can be about 20%. That is, in reality you can only get 160 l/min. This is quite enough to ensure the operation of a household pneumatic tool, tire inflation, painting and other small tasks. But for professional compressors, this figure is much higher and when choosing, you should focus on the power of the used pneumatic tools and other devices with which this compressor will then have to work. If the equipment needs to work in 800 liters of air, then at the inlet the air flow rate should be approximately 20-30% more. So you need to look for a device with a capacity of about 1000 l/min.

Available receiver capacity

For household data models, the indicator should be from 6 to 50 liters. This will be enough to do any homework. If you are looking for a unit for a workshop or a small service station, then it is better to look at the options that have a more capacious receiver - from 100 liters. For large industrial enterprises or construction sites, a model with receivers over 200 liters is recommended.

Pressure

This indicator can be measured in different units in atmospheres, mega pascals, bars, kg per cm3. The most common - Bar and MPa.

If the device is low-power and designed for domestic use, then it has a pressure of 6 to 8 bar. For professional models, the optimum pressure is from 8 to 10 bar. Such devices are able to cope with almost any of the most common tasks and equipment. If you need a professional specialized model for working with large-sized and powerful equipment, then choose compressors with a pressure of more than 10 Bar.

Features of installing an air compressor

Installation of air compressors can be stationary and mobile. Household models usually have the ability to quickly transport, they are mobile and easy to use. Professional because of their large weight and dimensions are usually installed permanently.

So, let's summarize. If you need a cheap option for solving current homework: painting, swapping, etc., then it is better to choose a high-quality household compressor. These models are not very large, can be stored in the garage without any problems and can easily cope with all domestic tasks.

If you are looking for a powerful device that has the necessary power and productivity, then you should consider more expensive semi-professional or professional models. In any case, the choice depends on how you plan to use the unit and what tasks to solve with it.

In our online store you can buy air compressors in Kiev, Kharkov and Odessa from leading brands at a very attractive price. We have a large selection of models of all types.

Related Content

Compressors and pumps: Best Sellers

Stay tuned for updates!

Subscribe to our Telegram channel and be the first to receive useful materials.

Subscribe