Choose a compressor – with a direct or belt drive?

The need to use a compressor often arises when performing many household tasks or in production where it is necessary to work with pneumatic tools, as well as to perform other tasks. These include tire inflation, as well as painting, cleaning, blowing surfaces or heating systems.

Often, drivers use compressor equipment for self-tuning their car, in this case it is simply necessary to use this device. Moreover, very often the need for medicine arises in him. In other words, such a device is often necessary in everyday life, so its choice must be thoughtful and careful.

The choice of a suitable option should be made on the basis of the required parameters and, accordingly, its purpose. However, the most important parameter is considered to be the method of transferring the torque of an electric motor; according to this principle, compressor equipment is available with a belt or direct drive.

Distinctive characteristics

Each compressor unit consists of an air receiver and an electric motor. A metal piston and various connecting components are used to compress the air in the equipment.

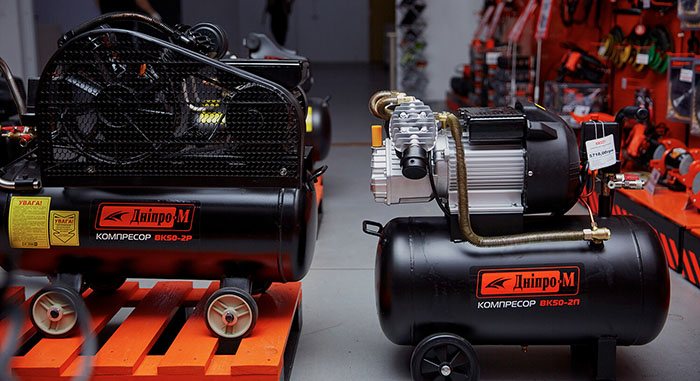

1. In compressor equipment with direct drive, the transmission element will be a piston head, its shaft and will be a motor shaft.

2. Belt devices are equipped with an additional transmitted mechanism – a belt with pulleys.

This difference is insignificant, but a number of factors depend on it, providing for the particular features of the equipment operation. First of all, equipping certain types of drive indicates the direction of use of the unit, indicates its appearance – for use in everyday life or more professionally, and also has an impact on performance, duration of work and resource.

The principle of operation of a direct-drive compressor

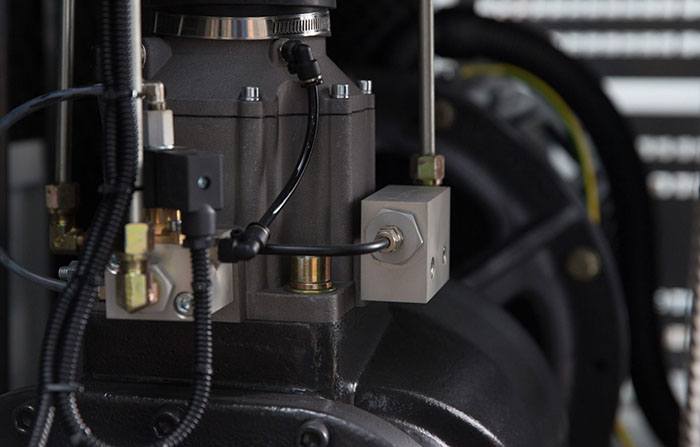

Such compressors are equipped with a piston and a working cylinder; there are two types of air valves in the lid – for air intake (suction) and air discharge (supply). The air is compressed due to the movements of the piston, which injects air through the intake valve. While moving, it squeezes the air, and when the pressure reaches the required value, then it opens the discharge valve, releasing the air to work with pneumatic equipment.

Thus, the transmission of air is carried out directly, since it is carried out without «intermediaries». This design makes such a compressor inexpensive and not difficult to work. Therefore, it is often used in everyday life, rather than for professional purposes.

How does the belt compressor?

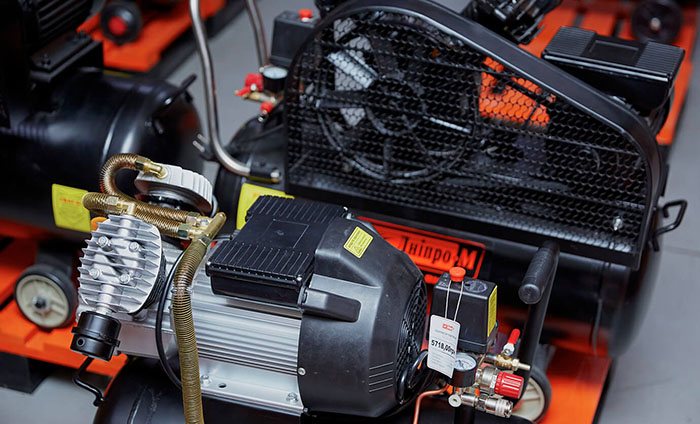

Transmission using a belt drive transmits the rotational energy of the electric motor to the movement of the piston, it consists of a flat belt and 2 pulleys.

1. The first pulley is called the leading, it is smaller in diameter, connected to the motor shaft.

2. The other pulley is called the slave or flywheel, it has a larger diameter, is connected to the piston head.

Air transmission is carried out without noise, smoothly, the flywheel is also responsible for determining the frequency of movement of the piston head. During operation, it reduces this figure, reducing wear on all mechanisms. An important option for the drive pulley is also the cooling of the air flow, which leads to less heating of the head.

Such features of belt-driven compressors make it more productive, it is able to work for several hours continuously. It is worth considering that during operation it does not heat up, despite the time of operation, this determines its frequent use for professional purposes.

The advantages of using direct-drive and belt-driven air blower

Consider the main advantages of using each type of pumping equipment. First of all, let's get acquainted with the devices running on a direct drive:

- differ in the small weight and the sizes, it is easier to store and carry them;

- low price due to inexpensive and simple design;

- eliminated regular breakdowns, is reliable and durable;

- lower energy costs.

Among the main advantages of belt driven compressors are the following:

- smooth start and work with no jerks;

- long time of use due to the cooling of the piston head;

- ease of repair – if the belt is cracked, you can simply replace it;

- reduction of noise and vibrations;

- the ability to work at any temperature – both low and high;

- protection from external influences due to the presence of a durable casing on the outside of all mechanisms.

As a result, productivity increases, which makes it possible to use such compressors in production, with professional use.

Features of use of each type of compressor equipment

Among the significant advantages there are several disadvantages that each type of pumping device has – both belt driven and direct driven. Consider first the direct-drive compressors.

1. Reduced operating life – despite the rare cases of breakdowns, yet these devices quickly fail.

2. The impossibility of long-term work due to rapid heating, it is necessary to turn them off from time to time to cool the engine.

3. High level of noise and vibrations.

Also, these compressors start abruptly, which leads to a surge of electricity due to the hard inclusion of the piston.

Among the disadvantages of belt compressors are as follows:

- large size and weight of the unit;

- complex maintenance process;

- It takes time about time to replace the belt due to its rapid wear.

However, despite these shortcomings, each of these options is often chosen for purchase, given these points.

The difficulty of choosing the right type of compressor equipment

Despite the characteristics of each of these units, everyone will be able to choose the best option for personal use. It is important to take into account that belt compressors are not only complex in design, but also more productive, due to which many choose them to perform professional tasks – for operation in production, huge workshops or service stations. In this case, the dimensions and weight are not significant, since the compressor is permanently installed at these enterprises.

For use in the home – in the garage or in the country, for a variety of everyday tasks better suited straight-drive compressor. This unit does not require increased maintenance, it is easy to carry, it can be stored in any convenient place.

The choice is yours. The main thing you need to have an idea about the purpose of the device and then choose the best option. This can also help managers of our online store. Thus, the buyer will be able to get the perfect option for personal use. Are you looking for car compressors? Buy in Kiev, Odessa, Kharkov, you can at 130.com.ua. Delivery in Ukraine.