Vibration Damping: What It Is and Why Soundproofing Doesn't Work Without It

Many car owners start improving cabin comfort with soundproofing. However, without a proper foundation — vibration damping — the whole system becomes ineffective. Why can’t these two layers replace each other? How are they different? And how to choose the right vibration damping for a car? Let’s break it down.

What is vibration damping?

Vibration damping is the first layer in a comprehensive vehicle soundproofing system. Its job is to suppress mechanical vibrations and resonance caused by driving, engine operation, bumps in the road, etc.

These materials are usually self-adhesive sheets made of:

- bitumen;

- rubber or butyl rubber;

- modified polymers.

They are applied directly to metal surfaces: doors, wheel arches, floor, trunk, roof. Thickness typically ranges from 1.5 to 5 mm depending on the area and required damping level.

How does vibration damping differ from soundproofing?

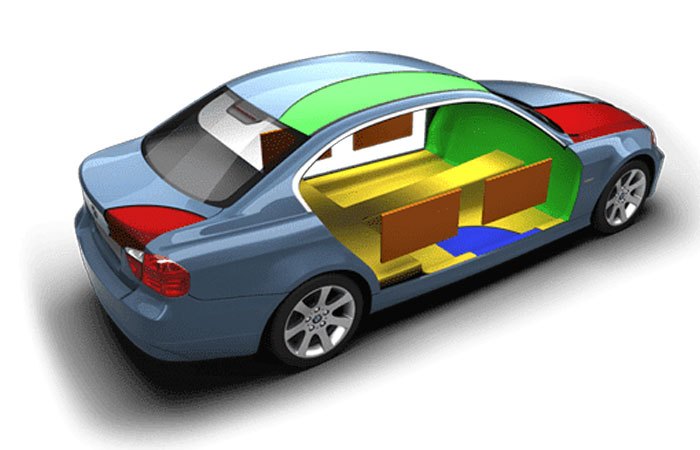

These two types of materials serve fundamentally different purposes:

| Parameter | Vibration Damping | Soundproofing |

|---|---|---|

| Main function | Absorbs vibrations and resonance | Absorbs sound waves |

| Applied to | Vehicle metal surfaces with vibration load | Over the vibration damping layer, closer to the cabin |

| Materials | Bitumen, rubber, foil | Polyurethane foam, felt, foamed polymers |

| Effect | Reduces rattling, hum, and vibrations | Decreases audible noise |

Without vibration damping, soundproofing quickly loses its effectiveness. If vibrations continue to travel through the car body, even thick noise-absorbing layers can’t fully do their job.

How to choose vibration damping materials?

When choosing materials, consider the following characteristics:

- Thickness and density — 2 mm is suitable for doors, while 3 to 5 mm is better for floors and wheel arches.

- Loss factor (LF) — the higher it is, the better the material dampens vibrations.

- Temperature resistance — materials must remain effective both in summer heat and winter cold.

- Adhesive type — choose materials with strong adhesion and moisture resistance.

At 130.com.ua, you can find both universal damping sheets and specialized solutions for arches, hoods, and trunks.

Correct installation sequence: how to layer properly?

Comprehensive soundproofing always starts with vibration damping. Here’s the basic process:

- Clean and degrease the metal surface;

- Apply vibration damping sheets with firm, even pressure using a roller;

- Install sound-absorbing materials over the vibration damping layer;

- Optionally — add thermal or moisture insulation (in arches or under the hood).

Only by following this order can you achieve real noise reduction and eliminate rattles and vibrations in the cabin.

Conclusion

Vibration damping is the foundation of automotive soundproofing. Without it, even the highest-quality soundproofing materials won’t perform well. Vibration damping targets the primary source — mechanical vibrations — before they become audible noise.

That’s why upgrading your vehicle should begin with damping: choose high-density materials, apply them properly to high-load areas, and then move on to noise insulation.