Car noise isolation: selection of materials and work. Part 1

Each driver must understand that if he is going to upgrade the audio system in his car, then without comprehensive noise isolation can not do. It will help to lay the foundation necessary for improving sound. Moreover, even without modernization of acoustics, after noise isolation, even the sound of an ordinary radio tape recorder and factory speakers will pleasantly surprise you. In addition, this will also provide additional riding comfort, as the cabin will be noticeably more comfortable due to a decrease in ambient noise.

Naturally, all this is true only for those cases when the sound insulation works were carried out correctly and using high-quality modern materials. In this article we will talk in detail about different materials, their features and proper application. And also give advice on sound insulation of the main elements of the body and interior.

Types of noise insulation materials

The noise insulation class actually includes three large groups of materials, which according to their main properties can be divided into: vibration-absorbing, noise-absorbing, sealants.

Vibration isolation

The name of this type of material speaks for itself. Their purpose is to reduce the vibration that occurs between the metal surfaces of the car body during driving.

It is very important to understand that any work should begin with vibration isolation, because it is the basis. You should not ignore this stage, otherwise it will be difficult to achieve a good result.

As for the materials themselves, in general terms it is a layer of mastic on a special foil material, which can have different thickness and hardness.

Most often they are self-adhesive, but some mounting options require heating. This must be clarified in advance, before purchase, in order to choose the most convenient material for you.

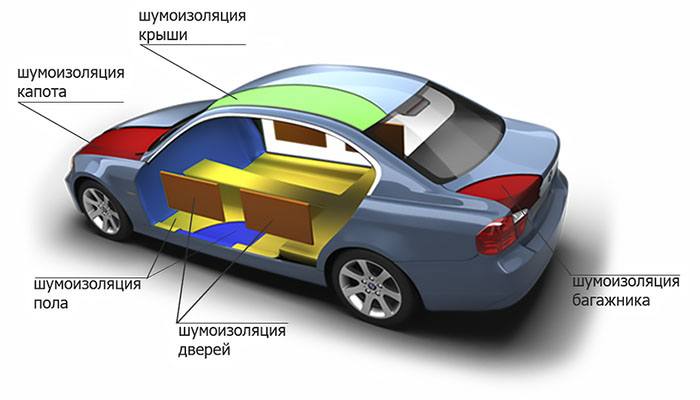

Vibration isolation is carried out in the following areas:

- doors;

- gender;

- roof;

- trunk lid;

- bonnet;

- partition of the engine compartment;

- wheel arches.

Soundproofing

Materials of this type are usually laid on a ready-made layer of vibration isolation. Their function is to absorb and heat the interior. There are two main types of sound absorbing materials.

The first is a thick layer of foam with a closed-cell structure. It has a pronounced pronounced thermal insulation effect.

Used for processing:

- floors in the cabin and trunk;

- roofs;

- hood covers.

The second has a softer structure, it is also made of foam, its difference is that it has a wavy or pyramidal surface. Thanks to such an uneven front surface, a good sound absorption effect is achieved. This material is more effective than flat analogues of the same thickness. And softness and suppleness allows the material to penetrate into the voids and fill them, in addition, it also facilitates the work with it.

Used for processing:

- doors;

- roofs;

- trunk lid;

- engine compartment partitions;

- the inside of the wheel arches.

Seals (anti-squeaks)

Using materials of this type allows you to get ridfrom squeaks or the so-called "crickets", which are very often observed in the interior of the car and many annoy. Also, anti-creaks are used in order to provide additional sealing at the joints of the plastic elements of the passenger compartment. They can also serve as a winding for electrical wiring.

Used for processing:

- ductwork;

- joints of plastic panels;

- places where door trim is attached.

Car noise isolation tools

Naturally, for all work to be carried out correctly, you need to not only choose high-quality material, but also prepare a set of tools that will allow you to perform the work as expected.

To conduct sound insulation of the car interior you will need:

- Tool for disassembling the interior-is necessary so as not to damage interior parts during work, protects against scratches, and does not damage painted, leather, chrome and other surfaces.

- The press roller is a special tool used for rolling material on the surface, thanks to its application you can ensure a snug fit, avoiding the formation of bubbles and non-glued areas. Please note that models with a plastic roller are not the most convenient, it’s difficult to roll Shumka well with such a roller, and they do not differ in durability.

- Scissors and a knife for cutting material-everything is extremely simple, scissors are most convenient to cut sheets into pieces of the appropriate shape and size.

- Heat dryer-you can’t do without it if you plan to use materials that require heating.

- Degreaser-it can be any solvent, white spirit and other similar compounds.

- Putty knife-it is needed in order to conveniently remove the remnants of old glue and factory noise insulation.

- Cleaning rags.

Work Suggestions

After you have decided on the material and selected the necessary tool, you can begin to work. If you do not have experience and do it for the first time, then it will not be superfluous to study some points that you must pay attention to, so that the work is not done in vain, and the result is high-quality. In particular, you should adhere to the following rules:

- Always glue any material only on a dry, pre-fat-free surface.

- When carrying out vibration isolation work, the material rolls very carefully and over the entire surface, spare the time and effort, everything must be done thoroughly.

- When choosing the thickness of the material, make sure that then all the plastic interior elements get into place without any problems.

- You must have a supply of mounting caps. In the process, they can break, this must be taken into account.

- Very carefully you need to monitor the location of the electrical wiring plugs and the order of fastening of parts. If you are not sure that you can remember everything well, you can take a picture, then there will be no special problems during assembly.

- It is recommended to perform work in a heated room, the temperature should not be lower than + 20C.

You can read in more detail about how work is carried out on vibration and sound insulation of various parts of the body of doors, trunk, roof, floor, wheel arches, etc. in the second part of the article.

We hope that our tips will help you find everything you need, and you can always buy materials for soundproofing a car salon in Kiev, Odessa or Kharkov in our online store 130.com.ua. We have materials of different thicknesses and different types. We work with leading brands: Comfort Mat, StP, Schumoff, Ultimate, Isolon and others.

Related materials

Noise insulation: Best Sellers

Stay tuned for updates!

Subscribe to our Telegram channel and be the first to receive useful materials.

Subscribe