Car noise isolation: selection of materials and work. Part 2

When conducting noise isolation, you must adhere to a certain procedure and rules that will achieve the correct effect. Let's take a closer look at the features of work in different parts of the car body.

Soundproofing doors

Doors need to be noisy, as it is this section that creates the foundation for building a high-quality speaker system. It also helps to reduce external sound exposure and makes door closure quiet.

Door preparation

First, the doors should be disassembled, then remove the completely old factory insulation, remove any glue with a solvent. If after opening the structures they saw that it was very dirty inside, it is recommended to wash the metal, and when the surface dries, it should be thoroughly degreased. Degreasing should always be carried out, it is important that the material holds firmly.

Vibration isolation

The first layer is recommended to apply a frame lattice, which can be used as a material of increased rigidity. Usually these are options for the installation of which heating is required. After cooling, they become tougher.

Then, the surface of the outer door wall from the inside is glued over the entire area with a dense vibration-insulating material having a thickness of 2-3 mm. Of course, it is obvious that when using a thicker one, the effect will be more noticeable, but the load on the loops will also increase, and the installation work itself will be more difficult.

In the next step, the material is glued from the outside to the inner wall of the door. You can do this in different ways, depending on what effect you want to achieve:

- standard-the entire surface is rolled up with one basic material, it is also used to seal mounting openings;

- reinforced-in this case, material that needs to be heated is used to process the mounting openings, it will provide rigidity;

- professional-the most effective, but also labor-intensive, in this version the holes are riveted with aluminum or special fiberglass linings, and vibration isolation is directly applied on top of them.

Remember to leave room for wiring. To reach the material, you can cut it in the appropriate places and then connect it under the wires when gluing, or you can partially remove the wires, completely seal the door (leaving the holes necessary for fastening) and then return the wiring back. Additional holes are required for attaching pistons, screws and rails so that door trim can then be put on. When gluing the material, make sure that it does not go beyond the border that is covered by the skin. Do not glue moving parts, for example, often inexperienced craftsmen can lay insulating material on the guides, set in motion by pressing the open/close button.

If the goal is to improve the sound quality of music in the cabin, it is recommended to additionally install special wooden spacers between the metal frame of the door and the speaker. The height of such an insert must be taken into account the distance to the skin, it should not interfere with the assembly of the door.

Soundproofing

Sound-absorbing materials must be glued to the inner surface of the casing. But if it has an uneven and very complex shape or there is a pile there, then it will be most optimal to glue the material on vibration isolation directly to the door wall. You will achieve greater effect if you take sound insulation with a convex surface.

Using splen and its analogues is not the best option when working in the door area. With the onset of cold weather, it may come off.

If there is a problem with creaks and rattle in the door card, then at the joints you can use a sealant-antiskrip.

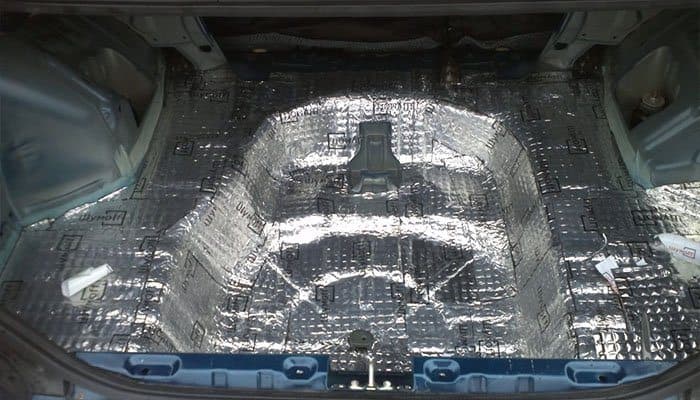

Soundproofing the trunk

Carrying out work in the trunk allows you to solve several problems at once:

- minimize the noise and buzz that penetrates the interior from the outside, especially true for owners of hatchbacks and station wagons;

- raise the sound of acoustics to but high level, in particular this applies to the subwoofer, as losses due to metal vibration in the luggage compartment are minimized;

- reduce heat loss.

Vibration absorber, which will go to the first layer, it is better to take a thickness of 2-3 mm. To enhance the effect, it is necessary to glue the material thicker on the main resonating surfaces or you can make a reinforcing mesh, similar to how it was done in the doors.

A material with a smooth structure is suitable for covering the floor of the luggage compartment. For walls and lids it is better to take sound insulation with an open structure. When gluing, make sure that the material fits snugly in all areas.

Soundproofing the roof

To reduce the influence of sounds penetrating from the street, and to increase comfort in the cabin, it is necessary to pay attention to the sound insulation of the roof. This procedure not only improves the quality of bass transfer, but also significantly reduces heat loss. Also, you will be pleased with the fact that during the rain you will not hear anything at all, there will be no sounds from the falling drops.

When preparing for installation, you should pay attention to the following points:

- In no case can stiffen ribs, if they are not ventilated, then moisture will begin to collect inside, and this condensate can then lead to trouble.

- Be careful when dismantling the casing; it is best to do this together.

- Like at the door, you need to work very carefully with the wiring, make sure that nothing is damaged, then it will be difficult to find a break after assembling the cabin.

Soundproofing arches

It is in the area of the arches that the sources of the main external noise are located, plus this section is constantly experiencing vibrational stress. If you want to significantly reduce noise, you need to conduct a comprehensive soundproofing arches.

External work

If lockers are installed on the car, they will have to be dismantled. On the outside, the arches are glued with a 3 mm thick vibration-absorbing material. Material is easier to handle for wheel arches.

Soundproofing for external use is not recommended, even if it is a moisture resistant material. Practice has shown that the effect of this will be negligible. It is better to use this material for processing from the inside in the cabin.

When gluing, carefully smooth the material with a special roller. There should be no bubbles and voids, the surface should be smooth and uniform. On top, it is recommended to treat all areas with liquid rubber or other similar composition. This will provide additional surface protection against sandblasting, mask vibration isolation and reduce noise arising from the impact of small particles on metal.

Soundproofing arches from the passenger compartment

The process of gluing soundproofing material from the inside is standard. The first layer is applied vibration isolation, the second-sound insulation. The best option is to glue Shumkov on interior parts covering the arches. But if this does not work, or their material does not allow the insulation to stick, then Shumka is superimposed on the vibration isolation.

Note that if you want to get a good and noticeable effect, then the approach should be comprehensive. If you perform only part of the described processing methods, you will most likely be disappointed. The effect will be very slight, perhaps even null.

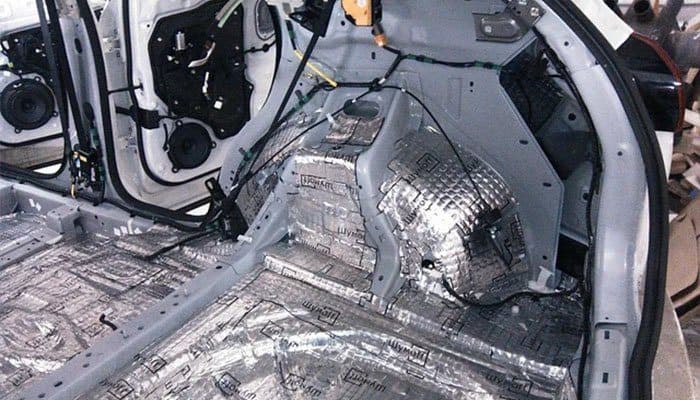

Soundproofing the floor

The floor in any car has a fairly large area. This is associated with great time and labor for dismantling the cabin. However, due to the fact that it has a relatively flat surface, it is more convenient and easier to glue vibration and noise insulation. Especially compared to door and trunk handling.

For the first layer, it is recommended to use vibration-absorbing materials thicker, in places where the greatest resonance is observed, it is better to apply material that needs to be heated during installation.

As a second layer, take waterproof soundproofing with a flat surface and a closed structure.

Make sure that all mounting holes are accessible, they do not need to be glued, otherwise it will be difficult to find them below the surface of the material.

Soundproofing engine compartment

In order to get a good effect and make the hum of the running engine quieter, in the engine compartment, sound insulation should also be done from two sides: from the outside and from the passenger compartment. This is one of the most difficult stages compared to processing other body parts. The main difficulty here is to disassemble the dashboard. This is due to the fact that a modern car is stuffed with different electronics, which is located in the area of the dashboard. Because of this, you need to shoot everything very carefully so that you can then collect it all just as correctly back. However, carrying out such work as a result will allow to suppress engine noise up to 50%. A significant plus, is not it.

For vibration isolation from the engine compartment, it is better to take the material thicker, or use heating materials to increase efficiency. Try to cover the entire surface, even in hard to reach places. The larger the surface, the better. It is recommended to use materials having a reflective surface (foil) as noise insulation, this will prevent possible overheating.

When processing a site from the passenger compartment, look when choosing a material so that its thickness allows it to then normally replace the dashboard.

When assembling, you can also take modelin, or any antiskrip. This will eliminate the “crickets” in the dashboard. There will no longer be a squeak that occurs when plastic elements rub against each other.

Soundproofing hood

In fact, the effectiveness of this procedure is not very high. We would recommend making the hood soundproof to owners of diesel cars in which the engine often rumbles loudly. In this case, it is advisable. Also, the processing of the hood may be necessary if it vibrates during riding.

With regard to the work on this site, it is best to glue the sound-absorbing material to the standard soundproofing hood. This is more convenient and will help to avoid problems with the fact that, inadvertently, you seal the ventilation openings.

Instead of a conclusion

Naturally, each car owner decides for himself in what volume and in what areas to carry out sound insulation. In any case, remember that the approach should be comprehensive, the only way it will be possible to achieve a tangible effect.

As a charming minimum, we would recommend spending:

- Noise insulation of doors is a basic necessary element, it should be carried out even for those who do not plan to modernize the speaker system. The effect here, when compared with the costs, is very good. At least immediately notice that the cabin has become more comfortable, quieter and warmer.

- If you want to achieve high-quality sound from a subwoofer, then you need to work with the trunk and, if possible, it will not be superfluous to glue the ceiling.

Noise isolation of other body elements is desirable, but in principle, you can do without it. Here, everything exactly depends on the individual needs and capabilities of each driver.

In the online store 130.com.ua you will find everything you need for soundproofing the cabin. We offer to buy noise insulation in Kiev, Kharkov and Odessa, at competitive prices. We have a large selection of various vibration and noise absorbing materials from leading manufacturers.